How Are USB Flash Drive and Memory Card Chips Manufactured?

Introduction

USB flash drives and memory cards have become essential storage devices in our digital lives, but few people understand how their core components – the flash memory chips – are actually produced. This article will explore the sophisticated manufacturing process behind these tiny yet powerful storage chips.

The Basic Structure of Flash Memory Chips

Flash memory chips consist of:

-

Silicon wafer substrate

-

Floating gate transistors (memory cells)

-

Multiple metal interconnection layers

-

Protective packaging

Step-by-Step Manufacturing Process

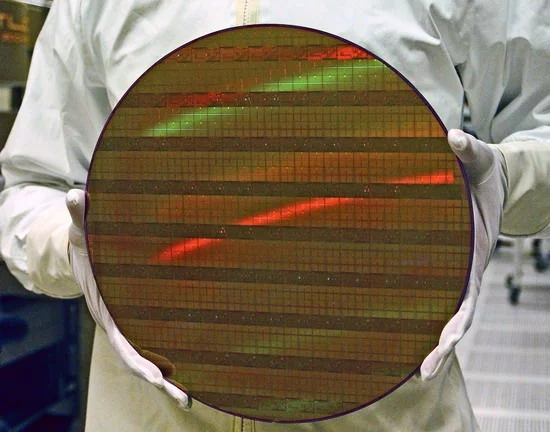

1. Silicon Wafer Production

The process begins with extremely pure silicon:

-

Silicon is refined from sand and purified to 99.9999% purity

-

Grown into single-crystal ingots using the Czochralski process

-

Sliced into thin wafers (typically 300mm diameter)

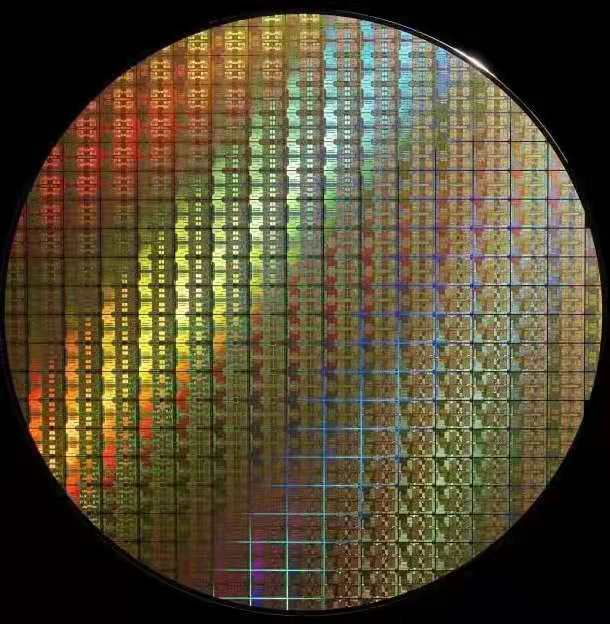

2. Photolithography

The wafer undergoes multiple photolithography steps:

-

Coated with light-sensitive photoresist

-

Exposed to UV light through a mask with circuit patterns

-

Developed to remove exposed/unexposed areas (depending on resist type)

-

Modern chips use EUV (extreme ultraviolet) lithography for smallest features

3. Etching and Deposition

-

Plasma etching removes unprotected material

-

Chemical vapor deposition (CVD) adds new layers

-

Physical vapor deposition (PVD) creates metal interconnects

-

This builds up the 3D NAND structure (for modern high-density chips)

4. Creating Memory Cells

Each cell contains:

-

Floating gate transistor structure

-

Charge trap technology (in newer designs)

-

Control gate, floating gate, tunnel oxide layers

-

Cells are organized in a grid pattern across the wafer

5. Testing and Quality Control

-

Electrical testing verifies each die’s functionality

-

Defective dies are marked and discarded

-

Only fully functional dies proceed to packaging

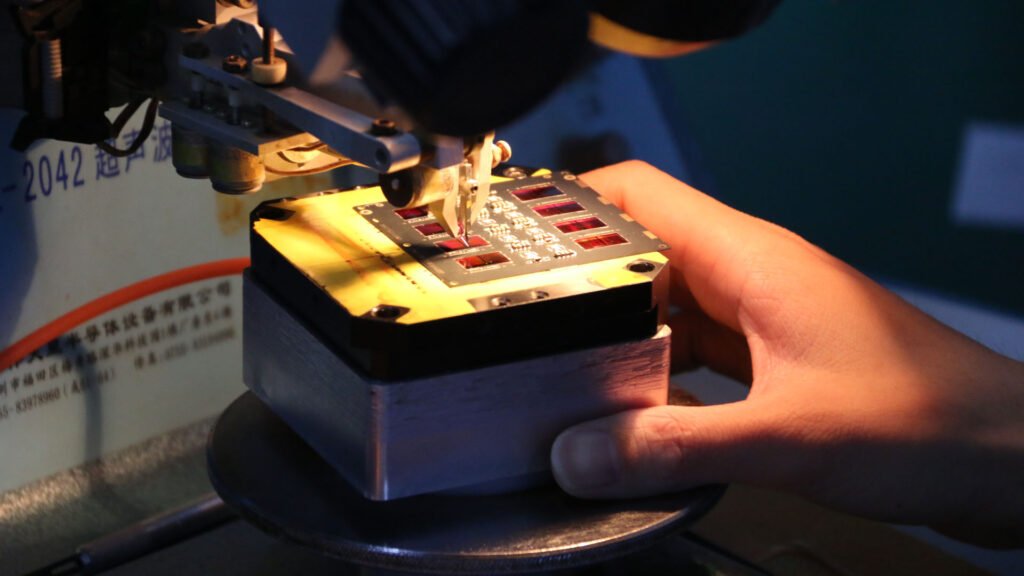

6. Packaging

-

Good dies are cut from the wafer (dicing)

-

Bonded to lead frames or substrates

-

Encapsulated in protective plastic

-

For USB/memory cards: additional controller chip is added

Special Considerations for USB/Memory Card Chips

High-Density Requirements

-

Uses 3D NAND technology with multiple stacked layers

-

Current technology reaches 200+ active layers

-

Enables terabytes of storage in tiny form factors

Endurance Optimization

-

Wear leveling algorithms in controller chips

-

Advanced error correction (ECC)

-

SLC/MLC/TLC/QLC tradeoffs between cost and durability

Future Trends

-

Transition to QLC (4 bits per cell) and PLC (5 bits)

-

Continued layer stacking (300+ layers)

-

New materials like ferroelectric RAM (FeRAM) in development

Conclusion

The production of flash memory chips is one of the most complex manufacturing processes in modern technology, requiring billions of dollars in fabrication facilities and nanometer-scale precision. This sophisticated process enables the affordable, high-capacity storage we rely on daily in our USB drives and memory cards.

Contacts

Abby ma

Whatsapp: +86 13049044451

Head Office

Shenzhen City,Guangdong Province,China

Support

supermemory.tech@gmail.com

Very useful knowledge!